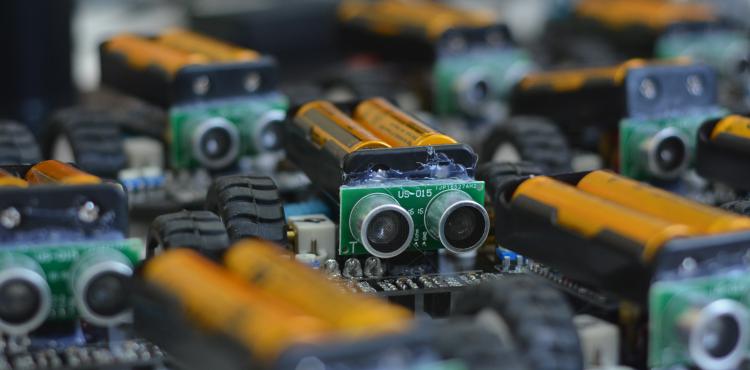

Industry 4.0 or Smart Industry is often understood as a collection of innovative technologies centered around digitalization, AI and IoT, in the service of more efficient and flexible production. For Inetum-Realdolmen, however, it's more than just an umbrella term. We want to tackle the real challenges of our industrial customers. Technology is a way of formulating an answer to these challenges, not an end in itself. Most cases are currently highly data-driven. Connectivity is the starting point, while also requiring cognitive elements. It's not enough to only install sensors, only capture data or start an analysis from scratch. Bringing all stakeholders to the table and drawing up a roadmap together, focusing on long-term added value, is the ultimate lever.

We do this based on our Positive Digital Flow vision and not from ad-hoc innovation: we take our customers on this journey towards a "factory of the future" step by step.